Dust Barrier Systems from Zipwall

The ZipWall Dust Barrier Technology was developed in 1997 as a result of Jeff Whittemore's expertise in the wood flooring industry and commitment to providing the best possible customer service. The ground-breaking method, which swiftly attracted attention and achieved success, enabled contractors to erect dust barriers efficiently. Jeff Whittemore, who holds 25 patents and is dedicated to innovation, keeps improving the ZipWall dust barrier system to suit the demands of the construction sector.

The ZipWall system is utilized for many different tasks, such as demolition, concrete cutting, painting, sanding, drywall and flooring installation, refurbishment, and restoration. The ZipWall dust barrier is regularly used for flood restoration, mold removal, and abatement, in addition to construction. The ZipWall system is also used by facility managers to keep their buildings operating efficiently while undertaking construction, remodeling, and refurbishment projects. Healthcare facilities, hospitality and retail establishments, manufacturing facilities, governmental and educational structures, transit hubs, and private houses are just a few of the places where the ZipWall dust barrier is used.

With products created in the US and distributed globally, ZipWall is a pioneer in the field of dust barrier systems. For practically any dust barrier installation difficulty in residential or commercial settings, ZipWall products provide a flexible and simple-to-use solution, including plastic and reusable fabric barriers, entryways, room dividers, and more.

The ZipPole system enables rapid and simple installation of temporary dust barriers, while the SLP2 and SLP6 systems are excellent for building a temporary wall. They stop the spread of dust and waste during construction or restoration. Contractors and other construction industry professionals may easily set up each of these systems without the use of ladders, tape, or damage, offering a practical and efficient alternative.

To create self-closing doors that aid in stopping the spread of dust and debris, use the ZipWall ZDC and ZDS ZipDoor Kits or the ZipWall 3070 Steel Frame Magnetic Door Kit for Doorways.

To meet particular requirements for the installation of a temporary dust barrier, ZipWall offers a variety of components that can be bought separately. These components include the Dust Barrier Foam Rail Cross Bars and T-Clips, ZipWall SDPK Tight Seal Side Clamps, ZipWall ZipHook Clamping Tools and Hanging Hook, ZipWall AZ2 Dust Wall Barrier Standard Zipper, ZipWall HDAZ2 Dust Wall Barrier Heavy-Duty Zipper, and the ZipWall CB1 and ZPCB1 ZipPole Dust Wall Barrier Carry Bag. The ZipWall NSP2 Replacement Non-Skid Plates are crucial extras that guarantee the poles don't slide around. During construction or maintenance, the ZipWall Caution Tape is a great way to alert workers to potential dangers or restricted areas, and the ZipWall GD2 Replacement Grip Disks can be used to replace disks that are worn out or damaged and support plastic sheeting or other materials.

The ZipWall dust barrier system is a widely-used tool for professional contractors across a range of industries and trades who need to protect against the spread of dust during construction.

One person can erect a 20 foot long ZipWall® barrier in less than one minute, saving a contractor time and money. This award-winning product has been honored by the press and hailed by professionals. It is recognized nationally and internationally as the best dust containment system available today.

EPA's New Renovation, Repair & Painting Regulations (RPP)

Are you prepared for the new requirements? Regulation compliance by contractors & firms for the renovation, repair and painting activities of target housing or child-occupied facilities built before 1978 for compensation takes effect April 22, 2010.

Lead dust must be contained by law, starting April 22, 2010

Sanding, cutting and demolition can create hazardous lead dust and chips by disturbing lead-based paint. Even tiny amounts of lead paint dust will poison children and adults. To protect against this risk, the EPA issued a rule requiring the use of lead-safe practices and other actions that will affect contractors. This was past into law on March 31, 2008.

Under the new rule, contractors that disturb 6 square feet or more of lead-based paint in homes, or child occupied facilities (built before 1978) must be certified in these new procedures and work practices before April 22, 2010.

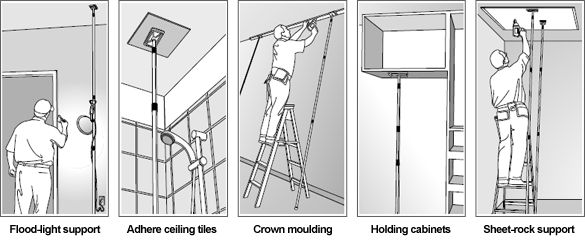

OTHER USES FOR ZIPWALL® POLES

ZipWall® poles are tough. They can hold weights of 70 lbs. or more depending upon the twist to lock it. A very strong twist can support as much as 110 lbs. Caution: Do not use for holding anything that could fall and cause injury.