Floor Machine Grit Rotary Brush

MAL-GRIT SCRUB rotary floor machine brushes offer solutions to a wide range of cleaning situations. Silicone carbide impregnated nylon bristles are self-replenishing as brush wears, offering unmatched value that outlasts floor pads over 100 to 1! That translates directly into time and cost savings. Featuring our water and chemical resistant TUFF-BLOCK for maximum life expectancy. All Grit Brushes must be run in a wet environment.

MAL-GRIT SCRUB High Productivity Stripping Brush:

- The most aggressive grit available

- This heavy gauge nylon with larger grit is used for stripping heavily soiled floors, such as concrete floors, in an industrial setting

- Trim Length: 1 1/2"

BEST USED FOR:

- Stripping: Terrazzo, Heavily Soiled Concrete

MAINTENANCE TIP:

- Rinse nylon brushes with hot water for 5 to 10 minutes to help the nylon recover its form.

- Always remove your brush or pad driver from the machine after use. Hang up to extend life. Always clean and rinse brushes thoroughly, especially after stripping jobs. Chemicals can be harmful to skin and eyes.

WARNING: Do not use brush or pad with flammable materials (fuels, solvents, thinner, etc.) or serious bodily harm or injury could result from possible fire or explosion.

Which Clutch Plate is Required?

We can supply clutch plates for most machines on the market. If you have original clutch plate, we will ask you for the center hole diameter of your existing brush. Measure the inside diameter from your existing brush or pad holder to obtain this information or Click Here for Brand Specific Clutch Plates.

Determining Diameters

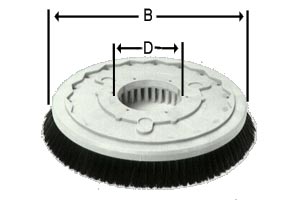

Block Diameter: Lay the brush on the bristles, block side up. Measure the actual outside diameter of the block (not the bristle flare). See photo below for reference (measurement B).

Center Hole Diameter: Lay the brush on the bristles block side up. Remove mounting hardware, if any. Measure actual inside diameter of the center hole. See photo below for reference (measurement D).

NOTE: Malish brushes are designed to fit each machine as shown, even though the block diameter listed on the charts may vary slightly from the diameter of the block originally supplied with the machine.

How to Break in a New Floor Machine Brush

Before using a new brush on carpeting, the brush should be broken in according to the following directions. This will eliminate possible excess drag by “tipping” the strands, removing any possible burrs caused by the manufacturing process.

Break-in Procedure

- Mount the brush on the floor machine. Follow ALL instructions included in your owner's manual.

- Find a rough textured floor surface, preferably unfinished concrete.

- Operate the machine on this surface. Run the machine DRY for approximately 15-20 minutes. The brush fibers will take a slight set or lean in the direction of machine rotation.

- Rinse the brush to remove any dirt caught when running machine. The brush is now ready to be used on carpeting.

Do you want a brush or a pad driver?

If your preference is to have a dedicated product, select a brush. If you have a variety of applications, your choice may be a pad holder. The surface being cleaned and the amount of dirt build-up will help determine the selection. The key to remember when ordering these items is the block diameter in relationship to the machine size. A brush is sized 2 inches smaller than the machine because of the flare of the brush fibers. Pad drivers are specified 1 inch smaller than the machine.

There is an easy way to cross check your selection from the Floor Machine Brushes and Clutch Plates section of this web site.

- A brush, long-trim pad driver, or short-trim pad driver without a riser, should be 2" smaller than the machine size.

- A pad driver or MIGHTY-LOK™ should be 1" smaller than the machine size.

Therefore, a 20" floor machine would use an:

- 18" brush, MAL-LOK™ or PAD-LOK™ without a riser

- or a 19" PAD-LOK™ or MIGHTY-LOK™

This rule applies to over 90% of the applications.